K-Technology

K Technology adds value

Your added value for “smart” production solutions of hollow plastic products. With K-Technology, Kautex customers achieve the perfect melt, the most homogeneous distribution, and seamless production sequences.

And best of all, as a customer you receive everything from one source. That saves you from the need to communicate with third party suppliers, and also from unnecessary waiting times.

Spare Parts

The Kautex Spare Parts portal makes ordering spare parts and accessories for your Kautex machinery* easier and faster. In just a few clicks, you can locate the part you need and order it online. When placing repeat orders, simply reuse your stored details.

Fast color change

With the patented RapidXchange technology, we have developed a way to reduce the purging process by up to 75%.

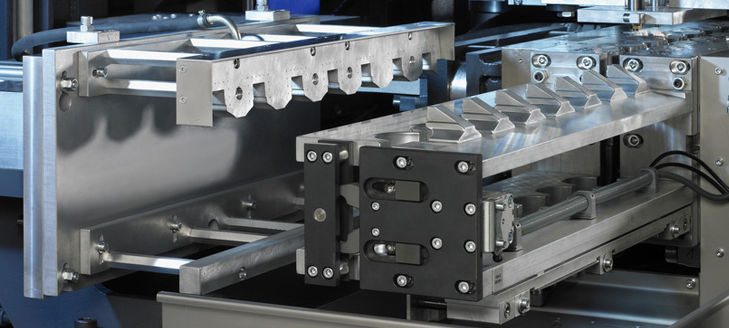

Fast mold change

A change of product is often associated with loss of production time and risks. KBB machines are designed to reduce such downtimes. The innovative Kautex fast-change system enables a mold to be changed in 15 minutes or less. In this system, every movement was analyzed by Kautex engineers.

Energy efficiency

The outstanding efficiency of the all-electric extrusion blow molding machines is confirmed by the latest test based on the Euromap 46.1 standards. Several Kautex machines of the KBB series achieved the best energy efficiency classification 10.

Virtual training

Trainee pilots practice on flight simulators before they are allowed to take control of real aircraft. And now there is a similar simulator for extrusion blow molding machines from Kautex Maschinenbau System GmbH.

Flying Knives

The interest in large, shallow plastic components has grown world-wide. Kautex Maschinenbau has recognized this market demand and developed a process that has attracted attention because of its cost-effective manufacturing and levels of quality that are unprecedented in this segment.

IntelliGate

The IntelliGate system from Kautex Maschinenbau System GmbH turns your Kautex extrusion blow molding machines into a complete production cell. The individual modules are coordinated to your machine by our experts and connected via the next generation interface.

K-Vantage

From mold validation in one of our international technology laboratories via simulation and all the way to complete line-engineering, everything needed for your turnkey solution is available.

All contacts quick and easy

We are here for you.

Service Hotline

You can reach us by telephone at