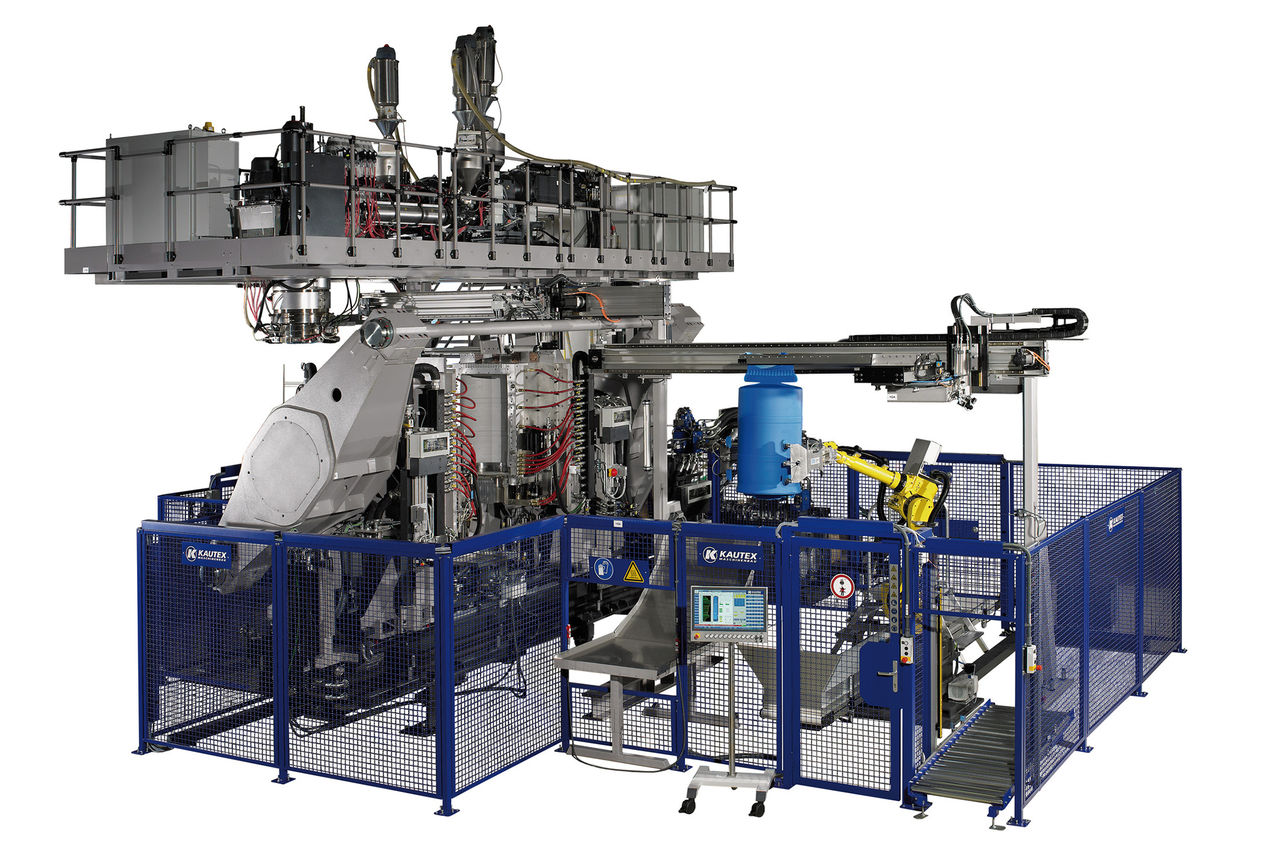

KSH200 extrusion blow molding machine

The KSH200 extrusion blow molding machine makes IBC production more reliable and efficient. It ensures the highest product quality and the lowest production costs. It’s a “smart” production solution for added value creating IBCs.

The KSH200 for IBCs has the focus on lowering product costs by reducing cycle times, material- and energy consumption and down-time. It sets new benchmarks in this field of “smart” production solutions.

High-maintenance parts were reduced, and virtual training sessions ensure efficient machine operation. The machine has the BC6 operating system with a moveable control panel.

Reasons for Kautex

Reduced product costs

Lower cycle times, lower production flash, lower energy consumption and reduced maintenance time

Highest output capacity

“Smart” production solution optimized for IBC products

Reduced down times

Comprehensive range of services all over the world

Optimized processes

Extrusion blow molding process optimized for IBC products

Safe operation

Virtual training for KSH machines available

Downloads on this topic

You can find brochures, pictures and videos in our media center.

The machine is optimized for IBC production and it guarantees the best possible plastic processing and highest melt quality, ultimately leading to the highest product quality. The KSH has a compact, space-saving structure. Being low in height with a small base area. This doesn’t just save space at the production location; the modules also fit into standard containers for shipping.

Low energy costs and PCR processing

The KSH200 runs without clamp shuttle operation to reduce energy costs. We move the parison to the mold rather than moving the complete clamping unit. Additional energy savings are achieved by the newest extruder generation and hydraulic circuitry. The machine was designed to make switching to PCR processing more straightforward.

The shortest possible down times and optimized IBC extrusion blow molding processes

With the KSH200 we have refrained from using high-maintenance system components as much as possible. We have optimized the blow molding process to such a degree that downtimes are reduced to a minimum. Virtual KSH machines are avail-able to provide realistic training for all operating processes. Our global service team can provide quick support in an emergency.

KSH range

We have developed the KSH range for mono and multilayer applications for the production of plastic drums and IBC´s.

All contacts quick and easy

We are here for you.

Service Hotline

You can reach us by telephone at