KBB range

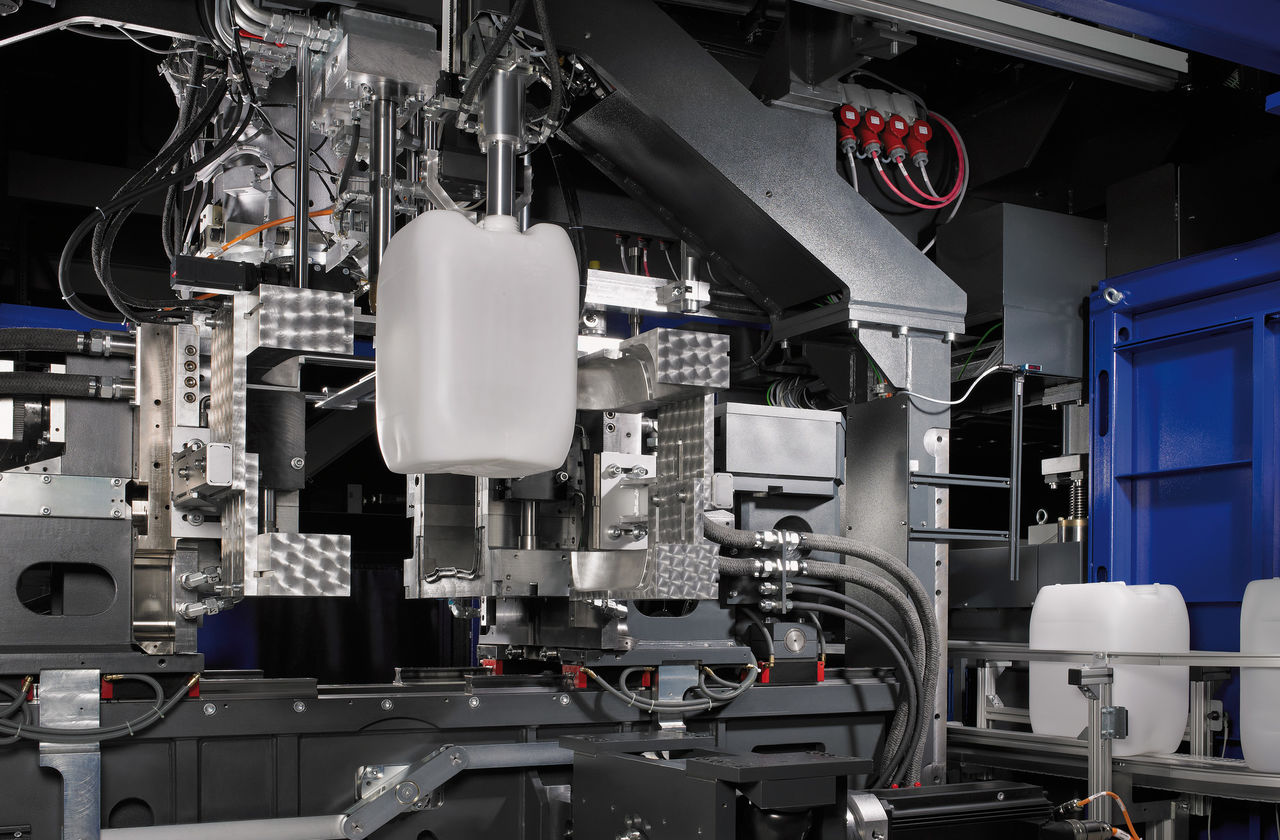

KBB extrusion blow molding machines - the gold standard in packaging

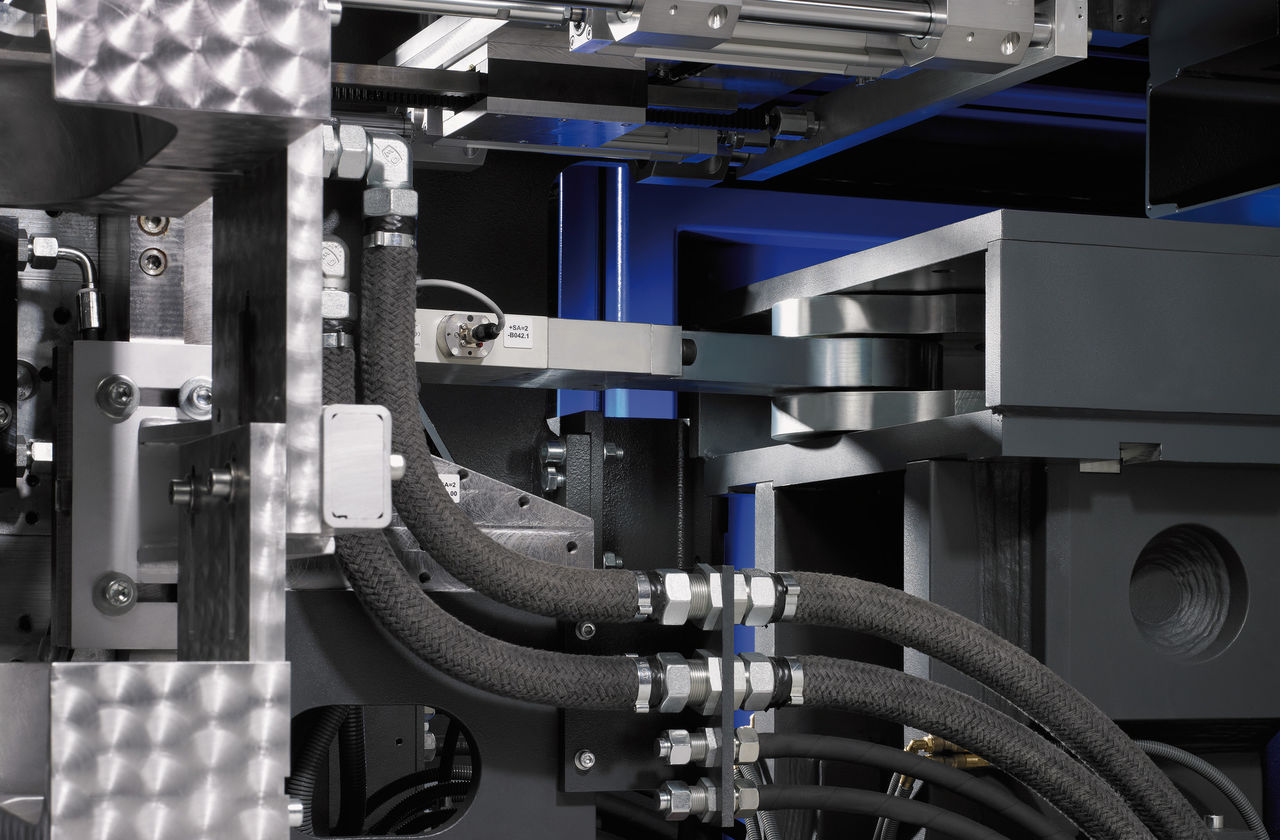

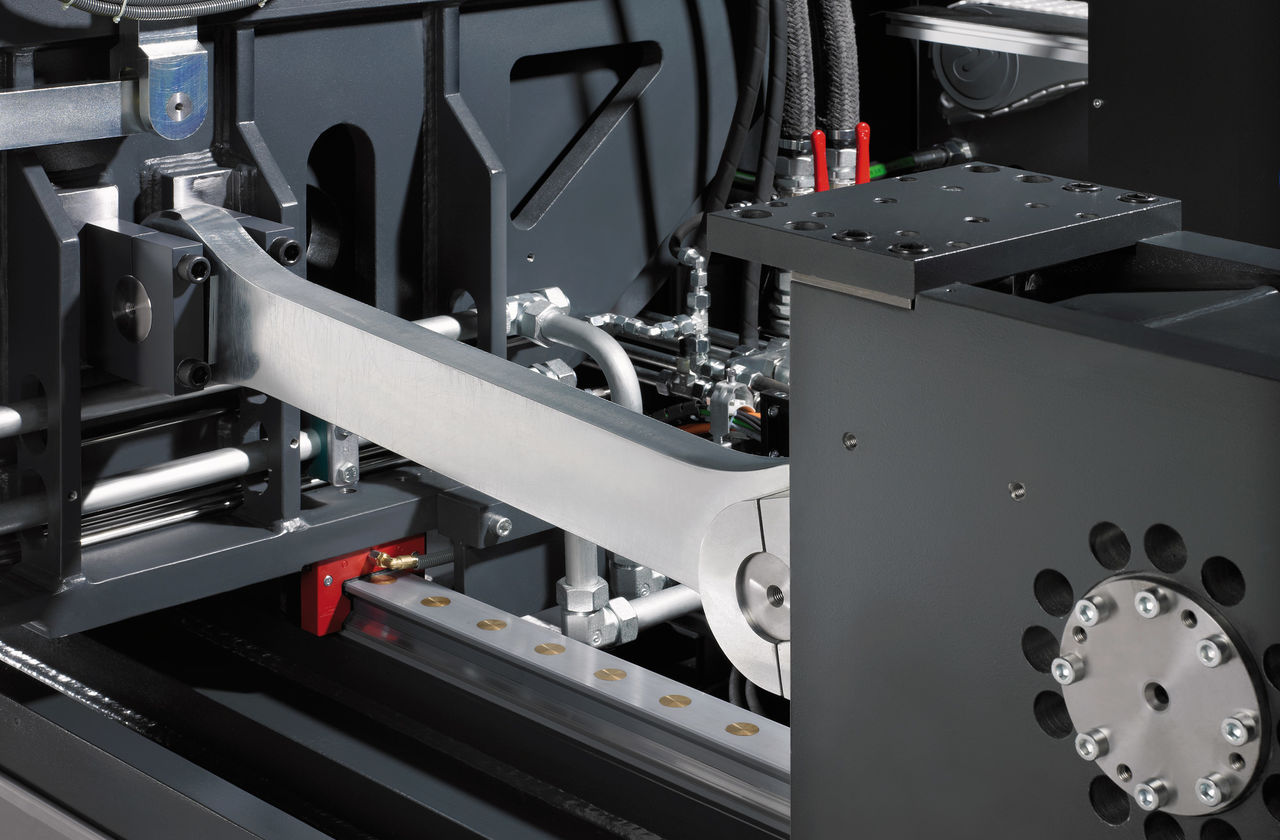

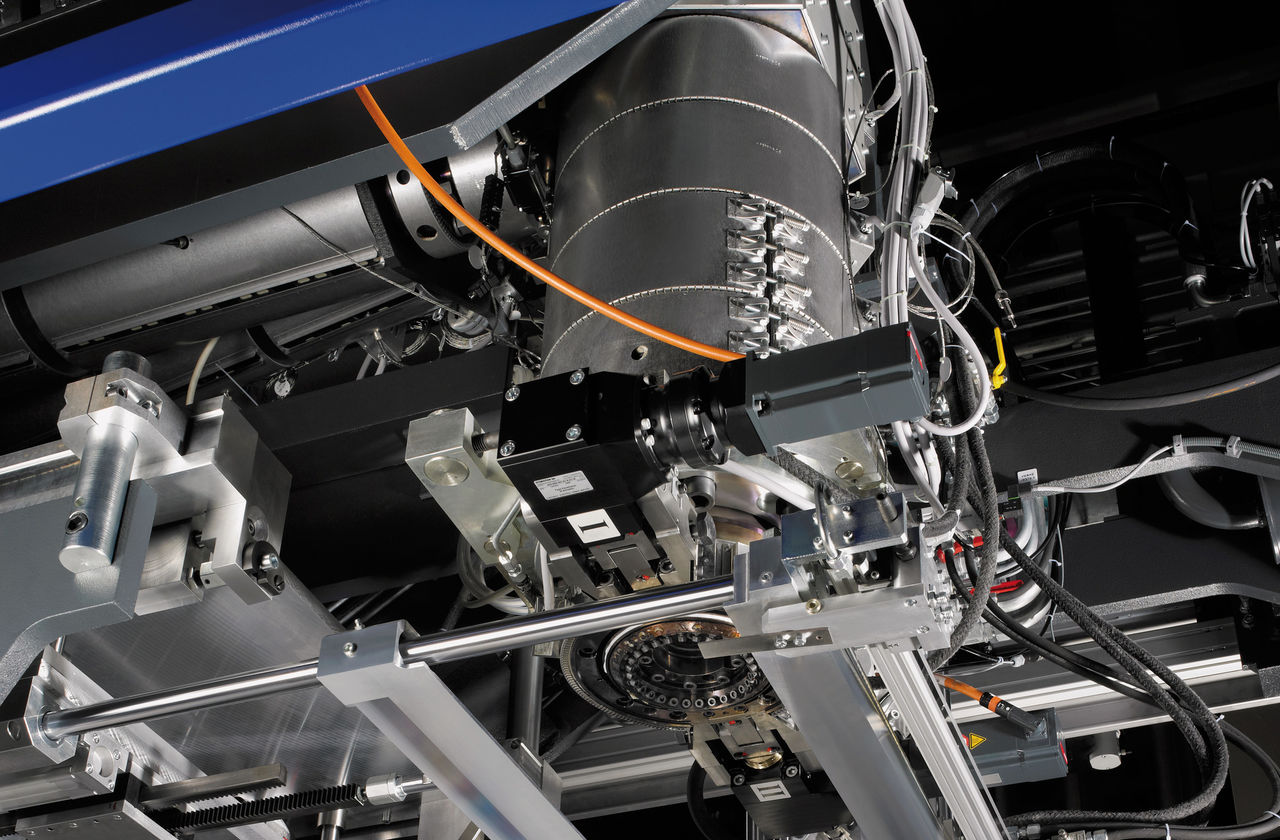

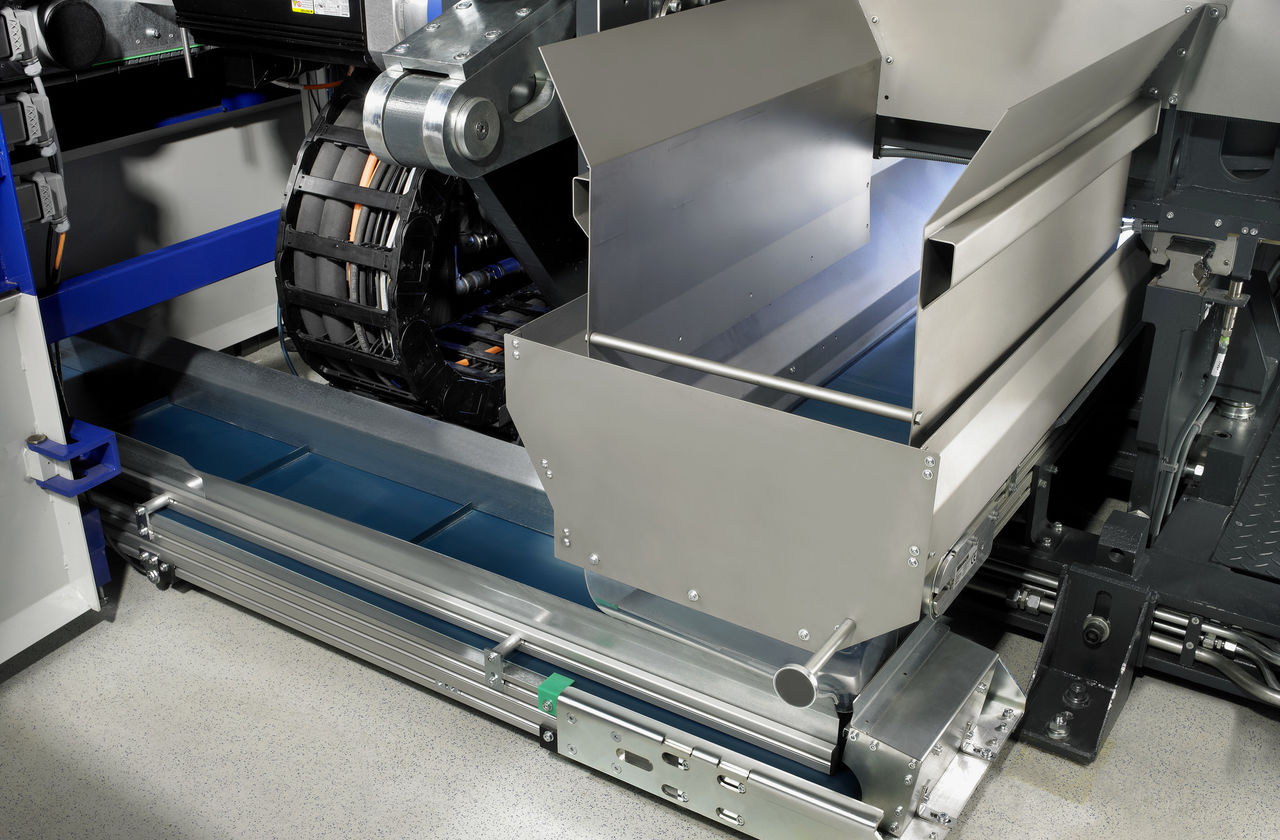

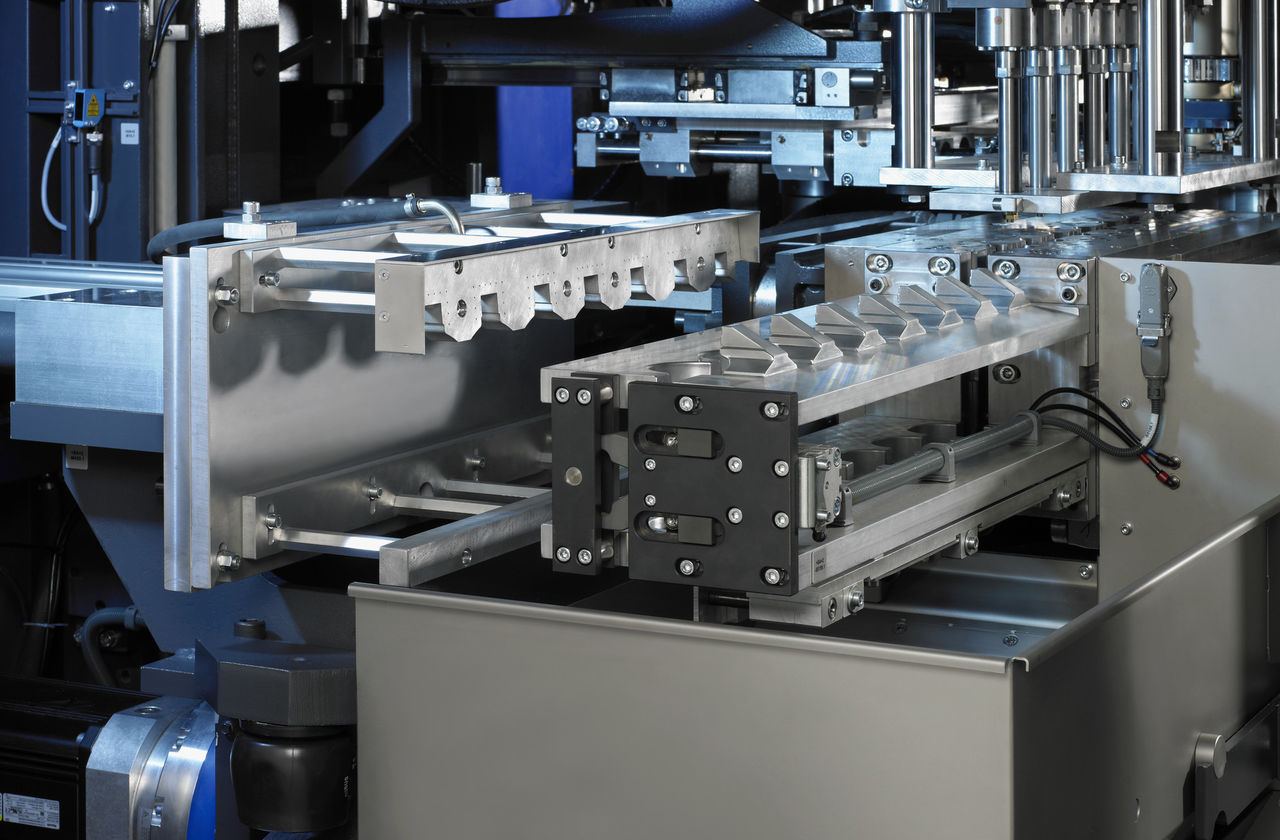

Maximum performance and minimum energy consumption: The all-electric extrusion blow molding machines from Kautex Maschinenbau System GmbH are the benchmark for bottle and jerry can production. KBB machines will transform your production processes to high-performance production thanks to the shortest cycle and fastest change over times.

The second generation, KBB evo, wins our customers over with even higher productivity alongside lower energy consumption and more attractive investment costs. All-electric extrusion blow molding machines don’t just set standards in terms of economy; they also do so in terms of ease of use.

The use of master batch is reduced significantly from the 3-layer ReCo3 right through to the multilayer co-extrusion production process. This is because a large proportion of regrind can be returned to the production cycle. You will also be hugely impressed by the machines’ outstanding energy efficiency, proven in tests in line with the Euromap 46.1 standards. Many models achieve the highest energy efficiency classification of 10.

KBB machines are available as single or double stations. The height of the clamping platens and the scope of the installation depth and the daylight opening represent a key distinguishing characteristic for the jerry can machines. The clamping forces of the bottle variants KBB40 to KBB100 range from 100 kN to 500 kN.

Technical Details

| KBB40D | KBB60D | KBB80D | KBB100D | KBB400S | KBB400D | |

|---|---|---|---|---|---|---|

| Mold | 610 | 760 | 960 | 1260 | 660 | 660 |

| Length (max. mm) | 430 | 430 | 430 | 430 | 700 | 700 |

| Thickness (mm) | 2x 150 | 2x 150 | 2x 150 | 2x 150 | 2x 250 | 2x 250 |

| Mold weight (max. kg) | 2x 200 | 2x 225 | 2x 300 | 2x 400 | 2x 600 | 2x 600 |

| Carriage shuttle stroke (mm) | 620 | 770 | 970 | 1270 | 670 | 670 |

| Clamp stroke (max. mm) | 250 | 250 | 250 | 250 | 400 | 400 |

| Blowpin stroke (max. mm) | 100 | 100 | 100 | 100 | 250 | 250 |

| Clamping force (kN) | 200 | 300 | 400/500 | 500 | 300 | 300 |

| Calibration force (kN) | 35 | 40 | 55 | 63 | 20 | 20 |

| Dry cycle time (s) | 2,20 | 2,30 | 2,80 / 3,10 | 4,5 | 3,1 | 3,1 |

Virtual machine views: KBB range

Experience the virtual 360° views of our machines.

A one-time registration in advance is necessary.

Reasons for Kautex

Reduced energy requirement

All-electric machines with recovery of braking energy and efficient melting

Maximum performance

Harmonious movement profiles in conjunction with the highest speeds and shortest additional process times

Precise

Highest repeat accuracy from the first second of the start of production

Cost effective

Lowest energy consumption, reduced use of material and shortest change over times

Sustainable

Material and energy savings plus PCR processing

K-Technology

Spare parts service

The spare parts storage at various locations worldwide, enables shortest delivery times and minimizes your downtimes.

Videos

To the Kautex Channel

All contacts quick and easy

We are here for you.

Service Hotline

You can reach us by telephone at