Machines

High-performance machines for sustainable production of hollow parts

An important chapter in Kautex’s company history started with the development of the world’s first extrusion blow molding machine for commercial use. Kautex’s founder Reinold Hagen started experimenting with the first thermoplastics at an early stage. His aim was to blow it up while still maintaining its shape. The first machine for blowing PVC parisons emerged in 1949.

Today our customers benefit from our broad range of production systems for the manufacture of many different containers such as bottles, jerry cans, fuel tanks, composite pressure vessels and much more besides. Reducing your production costs is a key consideration during our development processes. In order to achieve this, we are continuously striving to optimize the production time and reduce the amount of material. It is also important for us to guarantee you the highest possible degree of sustainability, user-friendliness, and system availability.

Innovative solutions throughout the production process ensure you will have outstanding product quality while down times are reduced. With our extrusion blow molding technology we will help you to permanently strengthen your position in the market with individual possibilities for configuration and quick-change systems to increase the efficiency of production. We will also support you around the clock with our fast, comprehensive and globally-focused services.

Virtual machine views

Experience the virtual 360° views of our machines.

A one-time registration in advance is necessary.

Reasons for Kautex

Quality production

Fewer customer complaints thanks to quality production

Cost effective

Low production costs thanks to availability and reduction of down time

Sustainable

Long service life, low energy consumption and the lowest possible consumption of raw materials

Worldwide service

Unique service packages, short response times and the ultimate in know-how

System provider

From before the melt right up to packing; everything from one source

KBB range

Maximum performance and minimum energy consumption: The all-electric extrusion blow molding machines from Kautex Maschinenbau System GmbH are the benchmark for bottle production.

KCC range

Performance oriented and cost efficient at the same time. The all-rounders of the KCC range are the result of consistent further development of these successful machine.

Skyreef series

With the new SKYREEF series, we now offer a modern and highly flexible production solution for high quality products from a single source with the full potential of our control system and services.

KSH range

We have developed the KSH range for mono and multilayer applications for the production of plastic drums and IBC´s.

KSB range

Kautex suction blow molding machines for mono and SeCo applications were developed for the production of 3D parts such as air ducts and different types of pipes.

KBS range

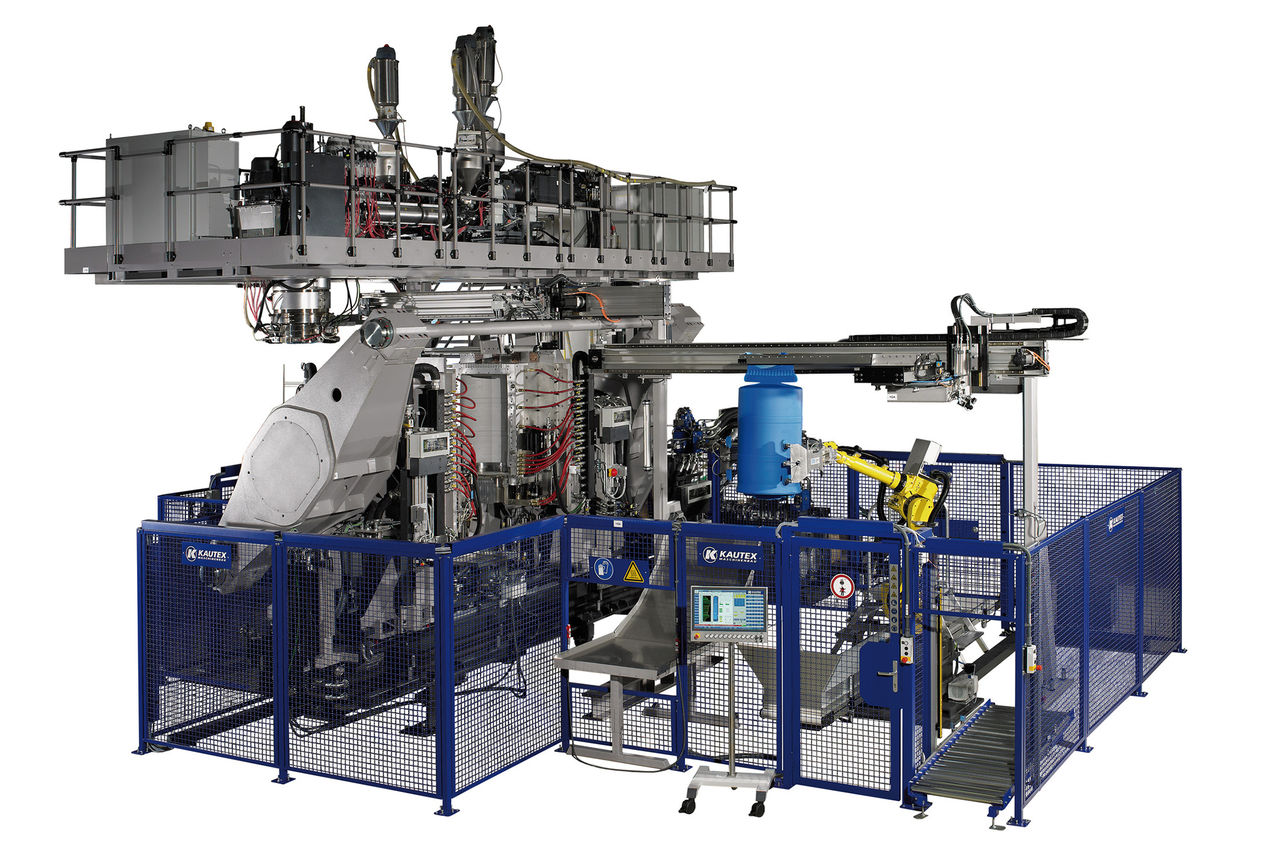

All-rounder with limitless possibilities. The extremely durable KBS range produces fuel tanks, canoes, seat shells, table tops and much more.

K3D range

The ultra-versatile machine for straight and bent parts such as air ducts or filling pipes stands out due to its impressive output rates while saving on energy and raw materials.

Die heads

Kautex has been producing die heads for decades. We develop, realize, and optimize our machines together with all extrusion blow molding components, and we provide a large bandwidth from mono to multilayer extrusion.

Sustainability

As mechanical and polymer engineers, it is essential that we ask ourselves how we can contribute to the sustainable handling of plastics. This sustainability is best achieved with a fully functioning recycling system.

Services

As a reliable partner, we wish to assist in the successful further development of your business with our services. Our international experts will quickly provide straightforward assistance.

All contacts quick and easy

We are here for you.

Service Hotline

You can reach us by telephone at